Welcome inside our own private Hackerspace !

Our (modest but efficient) industrial lab is composed of :

- Dedicated machines room

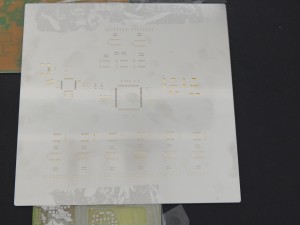

- 1 pick & Place machine (Mechatronika M10)

You can find more info on its features on http://www.mechatronika.com.pl/content/view/21/4/lang/en/

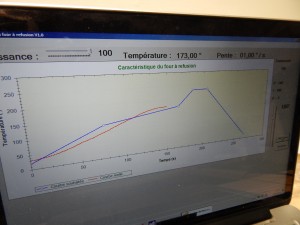

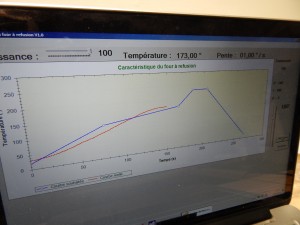

At the beginning of our project we check if a professional reflow oven could be a good solution; however 8000 $ for small series and prototyping is a little bit expensive, so we decide to create our own DIY reflow oven for less than 100 $ 😉

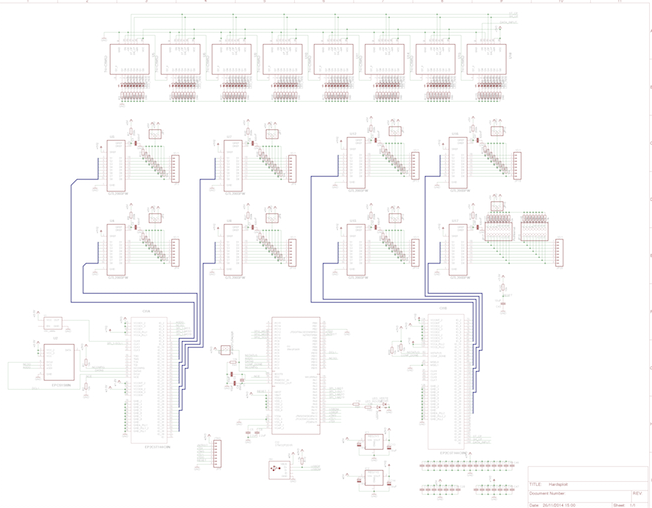

The power of the oven (thus the temperature inside it) is controlled by an electronic board that “switch on” or “switch off” the 220V power line. Our goal is to be able to adjust the temperature according to a consign via a classical PID system. All this stuff is located in the black magic box (DIY also)

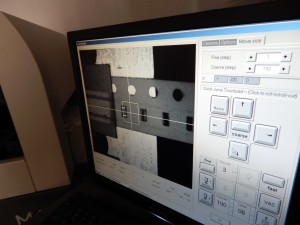

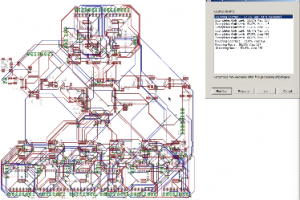

We created a dedicated tool and GUI to control the temperature inside the oven to follow precisely the temperature ramp associated with soldering SMT components

- Bunch of chemical products

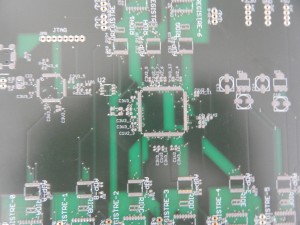

- Plenty of SMT component

- Air compressors (for the pick an place and for solder past)

- In short, common tools you need in a decent lab