We need to “hack” our machines to speed up the fabrication process of Hardsploit electronic boards :

That was the duration to produce one board:

- 5 mn to place the stencil above the electronic board

- 14 mn by board for the pick & place (component positioning)

- 10 mn of soldering in the oven

- +1 hour of debugging electronic boards (due to soldering issues)

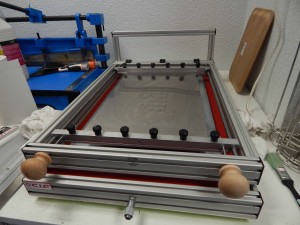

We decided to make some improvements : Stencil Dispenser Hacking (physically) !

- A / Order a larger stencil with smaller holes the goal is to position it in a more precise manner above the board (solder past dispensing improvement !)

- B / Add two specifics High Tech wood buttons (;-)) with screws to increase the tension of the stencil to improve solder paste dispensing (stencil positioning improvement !)

- C/ Tweak some speed parameters in our M10 pick & Place machine to speed up the process (component placement speed improvement!)

RESULTS :

- 30s to place the stencil above the electronic board

- 7 mn by boards for the pick & place

- 10 mn soldering in reflow oven

- No more or few short circuits issues to debug

Half of afternoon production batch finished, we succeed to improve our process :

Work continue ! (we have 60 more Hardsploit to finish 😉 )

Leave a Reply

You must be logged in to post a comment.